⭐⭐⭐⭐⭐ AUSTRALIA’S LARGEST RANGE OF NATURAL STONE PAVERS ⭐⭐⭐⭐⭐

⭐⭐⭐⭐⭐ AUSTRALIA’S LARGEST RANGE OF NATURAL STONE PAVERS ⭐⭐⭐⭐⭐

From $7.70 incl. GST / each

REQUEST A FREE QUOTE

✔ HIGH NON-SLIP RATING ✔ 100% PURE STONE ✔ POOL COPING

Matching pool coping : Drop Face | Bullnose | Bevel Edge

![]() PRICES For a great PRICE, extremely durable bluestone pavers with the epitome of bluestone’s natural beauty. We recommend you follow the following guidelines when purchasing our BLUESTONE: 12mm thick: tiles should be laid directly onto a concrete slab or great for balconies, decks or indoor floor tiles. 20mm thick: pavers can be laid as above OR onto a compacted road base into a wet slurry of sand and cement 30mm thick: pavers can be laid as both above or onto a compacted road base into a dry sand bed, great for tiling over easements or where you require water permeation. There will be some cats paw present in this stone. Generally, a tile will only have a MAXIMUM of 10-15% of surface coverage. Expect a dimensional or thickness variation of +-3mm. We HIGHLY recommend laying in a brick pattern with a 8mm grout joint.

PRICES For a great PRICE, extremely durable bluestone pavers with the epitome of bluestone’s natural beauty. We recommend you follow the following guidelines when purchasing our BLUESTONE: 12mm thick: tiles should be laid directly onto a concrete slab or great for balconies, decks or indoor floor tiles. 20mm thick: pavers can be laid as above OR onto a compacted road base into a wet slurry of sand and cement 30mm thick: pavers can be laid as both above or onto a compacted road base into a dry sand bed, great for tiling over easements or where you require water permeation. There will be some cats paw present in this stone. Generally, a tile will only have a MAXIMUM of 10-15% of surface coverage. Expect a dimensional or thickness variation of +-3mm. We HIGHLY recommend laying in a brick pattern with a 8mm grout joint.

![]() SIZES AVAILABLE are as follows….. 600×300, 400×400 800×400 in 12mm 600×300, 400×400, 500×500, 800×400, 1000×500 in 20mm and also 30mm thickness

SIZES AVAILABLE are as follows….. 600×300, 400×400 800×400 in 12mm 600×300, 400×400, 500×500, 800×400, 1000×500 in 20mm and also 30mm thickness

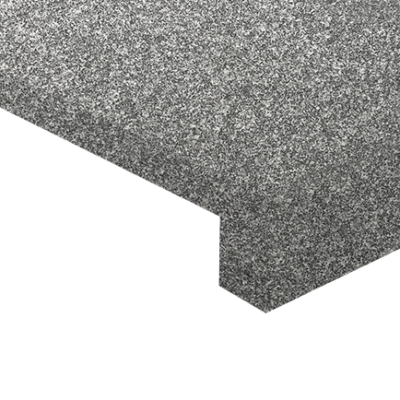

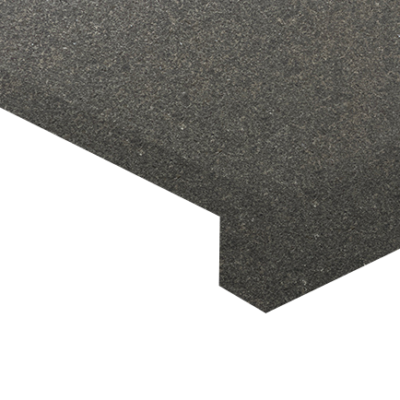

![]() MATCHING POOL COPING available in Drop Down, Bullnose, Bevel Edge The European has a medium grey colour with cool blue undertones. As a result, they make excellent pool pavers and pool coping tiles as they enhance the blue colour of your pool. If you need a hand or have any questions regarding bluestone, give our Stone Experts a call: (03) 9706 9767 or contact us here.

MATCHING POOL COPING available in Drop Down, Bullnose, Bevel Edge The European has a medium grey colour with cool blue undertones. As a result, they make excellent pool pavers and pool coping tiles as they enhance the blue colour of your pool. If you need a hand or have any questions regarding bluestone, give our Stone Experts a call: (03) 9706 9767 or contact us here.

![]() Installation Guidelines

Installation Guidelines

We recommend that you grade the pavers into 2-3 thickness groups prior to installation. This is easily done as you are taking the tiles out of the crates and will also mix any variations in colour through the job from different crates.

15mm is recommended to be ONLY layed in a rapid setting adhesive and please use a 6mm trowel as follows…. Notch out 6mm of adhesive on the slab and 6mm cross notched on the back of each tile. Also please lay in BRICK or STRETCHER BOND patterns and allow for a 8mm minimum grout joint to allow for any tile variations in length or width. DO NOT ACID WASH your pavers.

![]() Sealing

Sealing

Bluestone tiles and pavers can be sealed as a peace of mind to ensure bluestone stays in pristine condition. It’s highly recommended particularly in areas where there may be high spillage to protect the lustre of the bluestone tiles and pavers.

If you choose not to seal your tiles, make sure you clean up spills immediately to avoid staining the tiles. Use only a penetrating invisible type sealer (no colour change) similar to Tasman Chemicals STONE SHIELD and ALWAYS follow the sealer manufacturers instructions when applying. We stock a FULL range of suitable sealers.

![]() Cleaning

Cleaning

Do not use Hydrochloric acid for clean up as this can cause minerals present in the stone to react adversely.To clean prior to sealing simply pressure wash the stone and ensure nozzle is never closer than 300mm to the surface of the stone.

![]() Maintenance

Maintenance

Just sweep when needed. Bluestone responds well to high pressure cleaning with a domestic machine, please keep the nozzle about 300mm minimum away from face of the bluestone pavers and tiles. A solution of mild detergent and water can be applied prior to pressure cleaning.

Here we will discuss the different characteristics of these two distinct bluestone categorisations.

Generally speaking, Standard Grade Bluestone will have the following characteristics:

![]() A higher percentage of tiles or pavers containing naturally occurring catspaw, between 3-15% of the surface of the tile.

A higher percentage of tiles or pavers containing naturally occurring catspaw, between 3-15% of the surface of the tile.

![]() Cutting tolerances during the process of slicing the bluestone boulders up into tiles or pavers. In this case, a variation or tolerance allowance of +-3mm is to be expected. This leads to the occasional tile or paver being slightly out of square and is the reason why we recommend laying ONLY in a brick bond or stretcher bond pattern (which may fix these issues). If laying in adhesive, we recommend using a 6mm notch trowel to spread the adhesive BOTH on the slab and on the entire back of every tile or paver in a cross thatched pattern.

Cutting tolerances during the process of slicing the bluestone boulders up into tiles or pavers. In this case, a variation or tolerance allowance of +-3mm is to be expected. This leads to the occasional tile or paver being slightly out of square and is the reason why we recommend laying ONLY in a brick bond or stretcher bond pattern (which may fix these issues). If laying in adhesive, we recommend using a 6mm notch trowel to spread the adhesive BOTH on the slab and on the entire back of every tile or paver in a cross thatched pattern.

![]() In some rare instances where some Ferro particles may be in the catspaw, it should be noted that these can be hidden during the grouting process.

In some rare instances where some Ferro particles may be in the catspaw, it should be noted that these can be hidden during the grouting process.

![]() The non-slip rating is HIGHER due to the sawn surface finish during the cutting process.

The non-slip rating is HIGHER due to the sawn surface finish during the cutting process.

Premium Harkaway Bluestone comparison:

![]() Less naturally occurring catspaw, usually around 0-5% of any tile or pavers surface.

Less naturally occurring catspaw, usually around 0-5% of any tile or pavers surface.

![]() Variation or tolerance allowance of +-1.5mm is to be expected.

Variation or tolerance allowance of +-1.5mm is to be expected.

![]() Naturally occurring light surface pattern and colour variations may be present compared to standard grade.

Naturally occurring light surface pattern and colour variations may be present compared to standard grade.

![]() Surface finish is lightly honed, giving a slightly smoother finish, however, is still classified as a non-slip surface.

Surface finish is lightly honed, giving a slightly smoother finish, however, is still classified as a non-slip surface.

Hey there! Here’s a quick rundown on when your order might arrive:

We’ve got some flexible ways to get your goodies to you:

We’ve got the right tools for the job:

We team up with top-notch third-party shipping partners to bring your order right to your door. Curious about costs? Pop us a message with your preferred delivery method, and we’ll give you the exact rundown—no surprises!